What Is Indexable Shoulder Milling?

Indexable shoulder milling is a precision milling process used to machine sharp, accurate vertical or horizontal shoulders on a workpiece. It uses shoulder milling cutters fitted with replaceable carbide inserts that can be rotated or replaced to expose a fresh cutting edge, reducing downtime and tooling costs.

Shoulder milling is ideal for producing clean corners, steps, and precise edges in a wide range of materials, including aluminium, steel, stainless steel, and harder alloys. This method delivers high accuracy, excellent surface finish, and consistent performance in both production and custom applications.

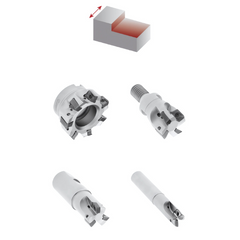

Indexable Shoulder Milling from Vortex & Palbit

We supply high-performance Vortex and Palbit shoulder milling cutters and inserts, designed for precise, reliable, and efficient milling operations.

Why Choose Vortex & Palbit Shoulder Milling Tools?

Accurate, sharp shoulders

Engineered for precision, these tools produce clean, square shoulders and defined edges with consistent quality.

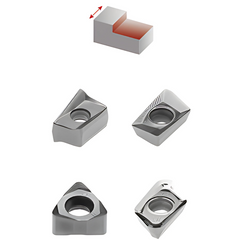

Durable carbide inserts

Vortex and Palbit inserts are made from high-quality carbide with advanced coatings, providing excellent wear resistance and long tool life.

Versatile material compatibility

Shoulder milling cutters are suitable for aluminium, steel, stainless steel, and titanium, making them adaptable for a wide range of applications.

Quick indexing and tool changes

Replaceable inserts make it easy to maintain peak cutting performance and minimise machine downtime.

Cost-effective machining

Multiple cutting edges per insert reduce tooling costs while maintaining high-performance milling.

Excellent surface finish

Precision-ground inserts deliver smooth surfaces, reducing the need for secondary finishing operations.

Shop Indexable Shoulder Milling Tools

Browse our selection of Vortex and Palbit indexable shoulder milling cutters and inserts for precise, efficient, and reliable machining of steps, corners, and shoulders.