Browse by Series

✅Multi (3-5) flutes

✅Coolant fluid washes the chips out of the hole

✅Increased tool life

✅Specially designed for threading on “through holes

✅Direct chip removal

✅Optimal for machines without external coolant

✅Multi (3-5) flutes

✅High rigidity and stability (anti-vibration)

✅Allows the reduction of cycle times via the use of higher cutting speeds and feeds

✅Internal coolant bore

✅Large number of flutes (5-8), resulting in significantly shorter machining times

✅Internal coolant bore

✅Cylindrical shank (Weldon shank available upon request)

✅Uncoated, smooth cutting edge

✅Internal coolant bore

✅Uncoated, smooth cutting edge

✅Internal coolant bore

✅Supports threads as small as ISO M1 x 0.25, and 0-80 UNF

✅The thread depth can be up to 5 x Thread Diameter (for some tools)

✅Multi (3-5) flutes

✅Supports threads as small as ISO M1.2 x 0.25, and 0-80 UNF

✅Multi (3) flutes

✅Supports threads as small as ISO M1.2 x 0.25, and 0-80 UNF

✅The thread depth can be up to 4 x Thread Diameter (for some tools)

✅Multi (3-4) flutes

✅Supports threads as small as ISO M1 x 0.25, and 0-80 UNF

✅Depending on the profile, the thread depth can be up to 3.5 x Thread Diameter

✅Multi (3-4) flutes

✅Depending on the tool, the thread depth can be up to 2 or 3 x Thread Diameter

✅Low cutting forces thanks to the short profile

✅Multi (3-4) flutes

✅Only internal threads supported

✅Multi (4-7) flutes

✅Depending on the tool, the thread depth can be up to 2 or 3 x Thread Diameter

✅Only internal threads supported

✅Increased cutting diameter; Results in more rigidity and stability

✅Shorter chips produced, ensuring process security

✅Tools available for the ISO & UN thread profiles

✅The thread depth can be up to 2 x Thread Diameter

✅Multi (3-4) flutes

✅Tools available for the ISO & UN thread profiles

✅The thread depth can be up to 2 x Thread Diameter

✅Multi (3-4) flutes

✅Integrated coolant bore (Tools without coolant available upon request)

✅The thread depth can be up to 2 x Thread Diameter

✅Multi (2) flutes

✅ Perfect Tool Selection

✅ Smart & Simple to use

✅ Boost Accuracy & Efficiency

✅ Cycle times supplied

✅ All control types included

Unified (UN, UNC, UNF, UNEF) Thread Mills

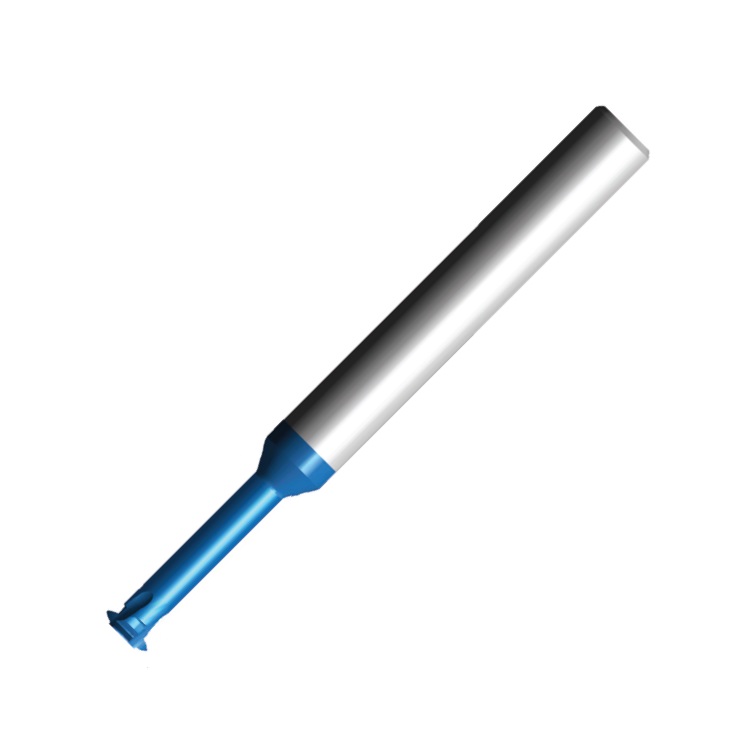

Carmex Unified thread mills are engineered for precision threading across all Unified standards, including UN, UNC, UNF, and UNEF forms. Each tool is manufactured from ultra-hard carbide and optimized for use on CNC machines to produce smooth, accurate, and consistent threads in every material.

Perfect for general and high-tolerance machining, Carmex Unified thread mills excel in steel, stainless, aluminum, and heat-resistant alloys. Their robust geometry ensures strong cutting edges, long tool life, and superior surface finishes, even at high spindle speeds.

These tools are ideal for aerospace, automotive, and general engineering applications requiring precision and repeatability.

✅ Covers all Unified thread standards (UN, UNC, UNF, UNEF)

✅ Reliable performance across materials and depths

✅ Exceptional tool life with accurate pitch control

Choose Carmex Unified thread mills — precision threading tools trusted by engineers worldwide.