Vortex Carbide End Mill Kits Compared

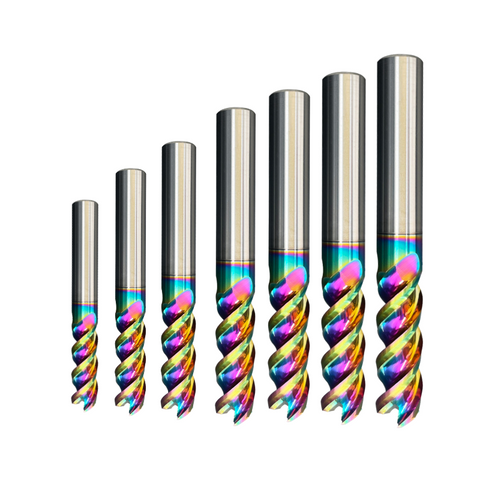

Technical Comparison: Vortex 4-Flute TiSiN vs 3-Flute Variable Hi-Helix DLC End Mill Kits

An engineer-level breakdown of geometry, coatings, applications, cutting data, and UK supply for Vortex carbide end mill kits.

Overview

The Vortex carbide end mill kits offer Engineers a compact selection of premium cutters, available in diameters from 3–12 mm. Two core variants exist:

- 4-Flute Square Edge, TiSiN Coated — designed for steels, tool steels, and mixed harder alloys where wear resistance and edge stability are critical.

- 3-Flute Variable Hi-Helix, DLC Coated — optimised for aluminium and non-ferrous machining where chip evacuation, reduced built-up edge (BUE), and high surface finish are priorities.

Kit Details

Vortex Carbide End Mill Kit — 4-Flute TiSiN

| Flute count | 4 |

|---|---|

| Geometry | Square edge, standard helix |

| Coating | TiSiN (Titanium Silicon Nitride) |

| Diameters | 3,4,5,6,8,10,12 mm |

| Strengths | High wear resistance, stable in steels, improved tool life at high temps |

| Limitations | Reduced chip clearance compared to 3-flute tools in softer alloys |

Vortex Carbide End Mill Kit — 3-Flute Variable Hi-Helix DLC

| Flute count | 3 |

|---|---|

| Geometry | Variable helix, high rake, optimised for non-ferrous |

| Coating | DLC (Diamond-Like Carbon) |

| Diameters | 3,4,5,6,8,10,12 mm |

| Strengths | Excellent chip evacuation, reduced BUE, low friction in aluminium |

| Limitations | Not ideal for ferrous materials due to coating breakdown under high temps |

Geometry & Cutting Mechanics

Flute Count

4-flute designs provide more cutting edges per revolution, resulting in finer surface finishes and reduced tool deflection in harder materials. However, chip space is reduced, making them less suited to soft or gummy materials.

3-flute variable helix tools strike a balance between chip clearance and edge strength. The variable helix interrupts harmonic vibration, reducing chatter — especially important on less rigid machines or long tool stick-outs.

Helix Angle

High helix angles (common in aluminium tools) produce a shearing action that improves surface finish and chip evacuation. Standard helix angles (in the 4-flute TiSiN) maintain edge strength for cutting tougher alloys.

Coating Properties

- TiSiN — High thermal stability, forms a protective silica layer at elevated temperatures (~800°C+). Ideal for dry machining or limited coolant in steels.

- DLC — Low friction coefficient (~0.1–0.2), prevents material adhesion and BUE in aluminium. Not stable under very high cutting temperatures, hence avoided in steels.

Recommended Applications & Strategies

4-Flute TiSiN

- Steels, stainless steels, tool steels, titanium alloys.

- Use with flood coolant or MQL where possible.

- Axial depth of cut (ap): up to 1xD; radial (ae): 10–40% depending on rigidity.

- Feeds: 0.03–0.08 mm/tooth (Ø6–12 mm typical).

3-Flute DLC

- Aluminium, brass, copper, non-ferrous alloys.

- High-speed machining (HSM) suitable; dry or with mist lubrication.

- Axial depth of cut (ap): up to 1.5xD possible with stable setups.

- Feeds: 0.05–0.15 mm/tooth (Ø6–12 mm typical).

Engineer’s Practical Notes

- Machine rigidity: For aggressive feeds on aluminium with the 3-flute DLC, ensure spindle and fixturing are rigid — chatter suppression relies on helix geometry and setup.

- Coolant strategy: DLC excels dry or with mist; TiSiN thrives under flood for ferrous machining. Avoid using DLC in prolonged steel cutting as coating may delaminate.

- Tool life: Expect longer edge retention with TiSiN in steels; expect smoother finishes and fewer tool changes in aluminium with DLC.

Delivery & UK Support

Protool operate from Wrotham, Kent — offering UK-wide delivery with free next-day shipping on qualifying orders. Engineers can also request cutting data sheets tailored to their machine and material.

Phone: 01732 887334 · Email: sales@protool-ltd.co.uk